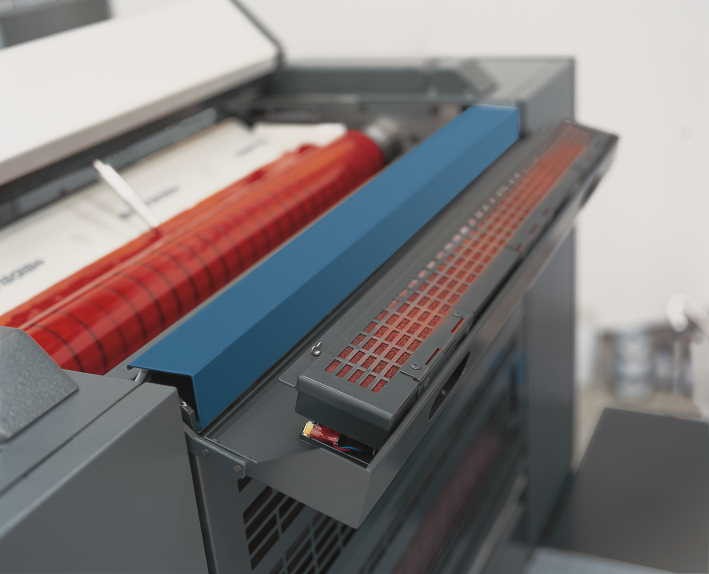

All images of Printing Machinery on this page are the courtesy of Heidelberger Druckmaschinen AG. Copyright by Heidelberger Druckmaschinen AG. For information click on: www.heidelberg.com

1. Dry Offset or Litho Printing (

Sheet fed or Web)

The principle that makes this type of coating superior to

conventional spot or strip release coatings is the fact that it remains

invisible to the naked eye without creating any unsightly blemishes such as

white haze or gritty textures on your graphics. There is no need for peeling or

rubbing and scratching to liberate the aroma. A gentle touch or brush of the

wrist will release a generous amount to sample.

Only odourless printing inks should be used to avoid any possible competition with the encapsulate. This is of special importance in the case of light or delicate fragrances.

The application of the encapsulate must be

through the last printing station

of the press to avoid any unnecessary additional shear

and possible damage to the capsules.

The ink duct must be perfectly clean and free of any

solvents, detergents or other chemicals. No other

ingredients can be added to this type of encapsulate because of the very

delicate nature of the capsule walls. The damping fluid section of your machine

cannot be used due to the water based properties of our

products and must be turned off.

It is possible to increase the coating weight by turning the rubber blanket over

with the fabric side facing up, if required.

It is not possible to print specified areas (spot coating) with this method due

to the water-based nature of this product. However, sometimes an old blanket can

be cut and reduced to simulate ‘spot varnishing’ on a litho press.

The capsules tolerate heat from

dryers of up to 190°C.

This presents an

advantage to drive off residual water to speed up the curing process.

Stacking the printed stock high does not break

the capsules, they only respond to shear and not to evenly distributed pressure.

Further processing such as cutting with guillotines, perforating and folding

does not present any problems

We can help to source the correct aroma,

carry out all the necessary testing,

followed by provision of proofing samples, assistance at the

coating stage and the final Q.A. evaluations.

All images of Printing Machinery on this

page are the courtesy of

Heidelberger

Druckmaschinen AG.

Copyright by

Heidelberger Druckmaschinen AG.

For information click on:

www.heidelberg.com

The application of the encapsulate must be through the last printing station of the press to avoid any unnecessary additional shear and possible damage to the capsules.

Only odourless printing inks should be used to avoid any possible competition with the encapsulate. This is of special importance in the case of light or delicate fragrances.

For this type of application a

special anilox roller should be created,

please contact us for details. The ink duct must be perfectly clean and free of

any solvents, detergents or other chemicals.

The capsules tolerate heat

from dryers of up to 190°C.

This presents an

advantage to drive off residual water to speed up the curing process.

Stacking the printed stock high does not break

the capsules, they only respond to shear and not to evenly distributed pressure.

Further processing such as cutting with guillotines, perforating and folding

does not present any problems

The principle that makes this type of coating superior to conventional spot or

strip release coatings is the fact that it remains invisible to the naked eye

without creating any unsightly blemishes such as white haze or gritty textures

on your graphics. There is no need for peeling or rubbing and scratching to

liberate the aroma. A gentle touch or brush of the wrist will release a generous

amount to sample.

Like the Flexographic method, gravure printing of encapsulates generates superior coating quality and is particularly suitable for the production of drawer liners and gift-wrap etc.

The application of the encapsulate must be through the last printing station of the press to avoid any unnecessary additional shear and possible damage to the capsules.

For this type of application a

Cylinder with the correct engraving must be

employed, please contact us for details. The ink duct must be

perfectly clean and free of any solvents, detergents or other chemicals.

The capsules tolerate heat

from dryers of up to 190°C.

This presents an

advantage to drive off residual water to speed up the curing process.

Stacking the printed stock high does not break

the capsules, they only respond to shear and not to evenly distributed pressure.

Further processing such as cutting with guillotines, perforating and folding

does not present any problems

The principle that makes this type of coating superior to conventional spot or

strip release coatings is the fact that it remains invisible to the naked eye

without creating any unsightly blemishes such as white haze or gritty textures

on your graphics. There is no need for peeling or rubbing and scratching to

liberate the aroma. A gentle touch or brush of the wrist will release a generous

amount to sample.

4. Silk Screen Printing (Flatbed or Rotary)

This printing method can produce some very high coating weights which allow multiple sampling or release from the same area. Unlike the other methods listed above, it can be seen with the naked eye, resembling an optical effect similar to silk varnish and remains translucent to allow graphics to show through.

The silk screen method becomes very useful if a specific area or a

special shape is to be applied to a part of the page.

We supply a ready to use encapsulation for this type of application for Flat bed

or Rotary Silk Screen. The screen(s)

should be made up with a mesh size from 70 to

120 T with a waterproof stencil.

All equipment must be scrupulously clean and free of any solvents, detergents or

other chemicals.

The coating weight is increased by this method to compensate for relatively

small areas of encapsulate. We recommend an area of 2 x 2 cm as the absolute

minimum with a coarse screen. Larger areas

generally work better and the coating weight can

be reduced by using a finer screen (120 T).

It is advisable to test the

adhesion of the capsules before committing

to a large print run.

The capsules tolerate heat from

dryers of up to 190°C.

This presents an

advantage to drive off residual water to speed up the curing process.

Stacking the printed stock high does not break

the capsules, they only respond to shear and not to evenly distributed pressure.

Drying is achieved by various methods of heat.

5. Spray and Air Knife Coating

Please contact us for specific advise for these coating methods.

6. Special encapsulates used as ingredients in specific formulations.

All the above are available as ready to print products or as concentrated encapsulates for mixing with clients preferred printing / coating bases. (Please consult our advice for compatibility with your material before mixing!)